Semiconductor shortage causing long delays for new cars and vans

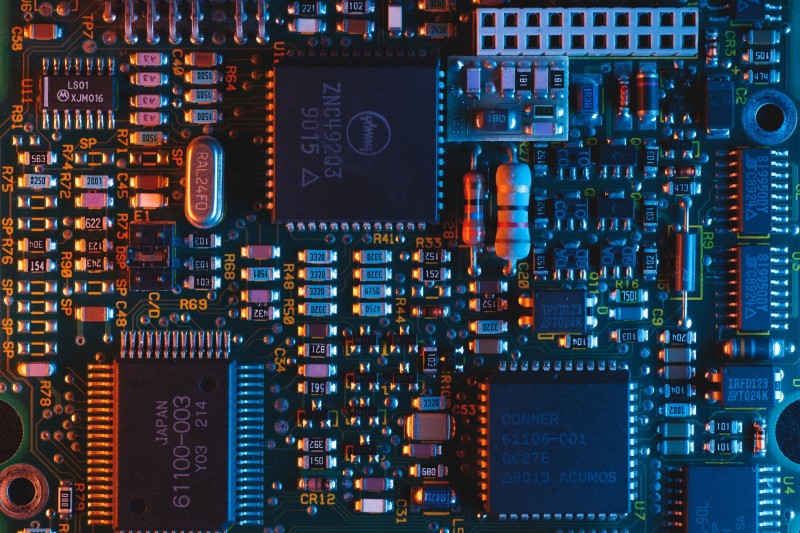

What is a semiconductor and why is it affecting our motor trade?

A semiconductor is a small micro-chip which can be found in almost every modern circuit board on the planet. In your phones, laptops, televisions etc. They have come to fame over the last few months which has been driven by a major shortage affecting many trades, but most notably the motor trade. With the average vehicle requiring over 1,500 semiconductors!

My business manages vehicles for individuals and small business fleets, so it’s been a bit of a challenging time for me. Rather than pull all my hair out, I advised my clients early in the year of the shortage of vehicles to come. Some didn’t believe me at the time and we are now joining the ever growing waiting list for new vehicles (earliest new deliveries now averaging June 2022).

But, why has this crisis happened?

The COVID-19 pandemic meant that less semiconductors were ordered to meet the anticipated drop in demand caused by the severe economic shock.

Lockdowns then created a massive surge in online ordering, increasing demand for computers for home schooling and home working, gaming devices for entertainment and electronic fitness devices to stay active. The resulting demand meant there were simply not enough semiconductors available to meet all the new orders.

It takes around two months just to make one chip and there are currently not that many companies in the world making them.

Taiwan experienced its worse drought in over 50 years during 2021 - A huge amount of water is required during the production process of making the chips. Japan also then had a major fire in the building that makes automotive semiconductors, again significantly reducing the manufacturing capacity.

What’s the current situation?

Many vehicles are being built but are then having to be stored until the semiconductors are available to be able to finish the vehicle before it can be delivered to the dealer. While waiting for the semiconductors many automotive manufacturers have implemented temporary factory shut-downs.

The current order-to-delivery lead time for semiconductors is now the longest it has even been at around 18 weeks!

What does this mean for you?

Due to the lower number of vehicles being manufactured, lead times for new vehicle factory orders with all manufacturers have been significantly extended and any stock vehicles available are being snapped up.

What should you do?

If you have a vehicle due to be replaced within the next 9 months, please contact me as soon as possible to see how I can help you.

Click Here to contact me today.